Epoxy flooring is a popular choice for both residential and commercial spaces due to its durability, easy maintenance, and versatility in design.

We will explore what epoxy flooring is made of, the different types available, how it is installed, and the benefits it offers.

Additionally, we will discuss the potential drawbacks of epoxy flooring, its applications in various settings, and how to properly maintain it.

By the end, you will have a better understanding of whether epoxy flooring is the right choice for you.

What Is Epoxy Flooring Made Of?

Epoxy flooring is composed of a two-part system that includes epoxy resin and a hardener, which chemically react to form a hard, durable, and seamless surface. This process creates a flooring solution that is both highly resilient and visually appealing, making it ideal for a variety of applications in industrial and commercial settings.

What Are The Different Types Of Epoxy Flooring?

There are several types of epoxy flooring, each designed to cater to specific needs and environments, including self-leveling epoxy, epoxy mortar floors, quartz-filled epoxy floors, anti-static epoxy floors, and epoxy flake floors.

Self-leveling epoxy flooring is perfect for areas that require a seamless, smooth surface, such as laboratories, hospitals, and manufacturing plants.

Epoxy mortar floors, on the other hand, are ideal for heavy-duty environments like warehouses and automotive garages due to their exceptional durability and impact resistance.

Quartz-filled epoxy floors provide a decorative yet long-lasting solution for commercial spaces like showrooms and retail stores, offering both aesthetic appeal and durability.

For environments sensitive to static electricity, anti-static epoxy floors are the go-to choice, widely used in server rooms, electronics manufacturing facilities, and laboratories.

Epoxy flake floors, with their colorful and textured finish, are commonly found in areas looking for a blend of style and functionality, such as residential garages, gym facilities, and commercial kitchens.

How Is Epoxy Flooring Installed?

Installing epoxy flooring involves a systematic process that starts with surface preparation and ends with the application of the epoxy coating. This meticulous procedure, often undertaken by professionals ensures a durable, seamless, and aesthetically pleasing finish.

What Are The Steps For Preparing The Surface For Epoxy Flooring?

Proper surface preparation is crucial for the success of epoxy flooring installation, involving steps like cleaning, repairing cracks, addressing moisture issues, and ensuring the concrete substrate is ready for the epoxy application.

Starting with cleaning, this step removes dirt, grease, and other contaminants that could hinder the epoxy’s adhesion. A clean surface ensures that the epoxy can bond properly with the substrate, leading to a more durable finish.

Next, crack repair is essential to prevent cracks from expanding and compromising the epoxy’s integrity. By filling and sealing cracks, you create a smooth surface for the epoxy to adhere to, prolonging the floor’s lifespan.

Additionally, moisture control is crucial to avoid bubbling or delamination issues. Properly addressing moisture concerns before applying epoxy helps maintain a stable substrate, allowing the epoxy to cure evenly and securely.

What Are The Steps For Applying Epoxy Flooring?

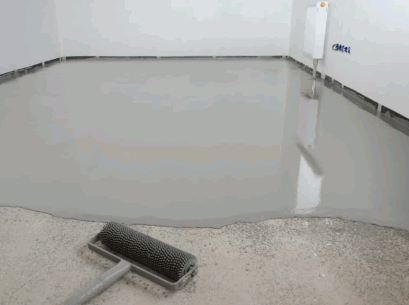

The application of epoxy flooring involves mixing the epoxy resin with the hardener and applying the mixture evenly to create a seamless surface that is both durable and visually appealing.

Proper mixing of the epoxy resin and hardener is crucial to ensure chemical reactions that form a strong bond between the two components. Once mixed, the application process requires precision to achieve a smooth finish. Tools like squeegees or rollers are commonly used to evenly spread the epoxy mixture. It’s important to work in small sections at a time to ensure consistent coverage and avoid unevenness.

After application, the curing time of epoxy flooring can vary depending on factors such as temperature and humidity. It is essential to follow the manufacturer’s instructions for proper curing, as this directly impacts the durability and longevity of the floor. A well-cured epoxy floor will provide a seamless and resilient surface that can withstand heavy traffic and various environmental conditions.

What Are The Benefits Of Epoxy Flooring?

Epoxy flooring offers numerous benefits such as exceptional durability, easy maintenance, chemical and stain resistance, and versatility in design, making it a top choice for both industrial and commercial applications.

Durability

Epoxy flooring is known for its industrial-grade durability, offering exceptional strength and wear resistance even in high-traffic and demanding environments.

This durability is due to the unique chemical composition of epoxy, which forms a hard, protective surface when applied to floors. The seamless nature of epoxy flooring prevents stains and moisture from seeping into the concrete substrate, enhancing its longevity. Epoxy coatings are formulated to resist chemical spills, making them ideal for industrial settings where harsh substances are frequently used. The ability of epoxy to withstand heavy loads and frequent foot traffic without deteriorating ensures that it remains a popular choice for warehouse floors, garages, and manufacturing facilities.

Easy Maintenance

One of the standout benefits of epoxy flooring is its ease of maintenance, thanks to its seamless surface and optional anti-slip coatings that make cleaning simple and efficient.

Epoxy flooring’s seamless surface not only simplifies the cleaning process but also contributes to maintaining a neat and polished appearance. Anti-slip coatings play a key role in ensuring safety without compromising the simplicity of upkeep. The smooth finish of epoxy flooring eliminates the need for grout lines or seams where dirt and grime can accumulate, making it a breeze to wipe or mop clean. This feature is particularly advantageous in high-traffic areas or commercial spaces where cleanliness is crucial.

Chemical And Stain Resistance

Epoxy flooring is highly resistant to chemicals and stains, making it an ideal choice for industrial settings where chemical spills are common.

Due to its durable nature, epoxy flooring forms a seamless surface that is impermeable to liquids, preventing them from seeping into the underlying substrate. This characteristic not only helps in maintaining a clean and safe working environment but also simplifies the cleaning process.

The chemical-resistant properties of epoxy flooring make it resilient against a wide range of substances, including acids, solvents, and oils. This resistance ensures that the floor remains intact even when exposed to harsh chemicals, prolonging its lifespan and reducing maintenance costs.

Versatility In Design

Epoxy flooring offers unmatched versatility in design, allowing for various aesthetic options such as epoxy flake floors and decorative gravel, making it suitable for both functional and decorative purposes.

The use of epoxy flakes can add texture and depth to the surface, providing a unique look that can mimic the appearance of terrazzo or granite. Using decorative additives like metallic pigments or quartz aggregates can enhance the visual appeal and create a luxurious finish.

Custom color choices further expand the design possibilities, allowing for endless combinations to match any interior décor or branding scheme. Whether it’s a sleek and modern office space, a vibrant retail store, or a durable garage floor, epoxy flooring can be tailored to suit the aesthetic needs of any setting.

What Are The Applications Of Epoxy Flooring?

Epoxy flooring is suitable for a wide range of applications, including industrial and commercial settings, high-traffic areas, chemical plants, and healthcare facilities, due to its durability, resistance, and aesthetic versatility.

Commercial And Industrial Settings

In commercial and industrial settings, epoxy flooring is favored for its durability, easy maintenance, and resistance to wear and tear, making it ideal for manufacturing plants and warehouses.

One of the specific benefits of using epoxy flooring in these environments is its ability to withstand heavy machinery and high foot traffic. This durable flooring solution can handle the weight and movement associated with industrial workspaces without cracking or showing signs of wear easily.

The seamless nature of epoxy flooring makes it a hygienic choice for environments where cleanliness is paramount. The smooth surface is easy to clean, preventing the accumulation of dirt, dust, and other contaminants that can compromise the safety and aesthetics of the space.

Epoxy coatings offer chemical resistance, protecting the underlying concrete substrate from spills or leaks that are common in industrial settings. This safeguard extends the lifespan of the flooring and reduces the need for frequent repairs or replacements, saving time and maintenance costs in the long run.

Residential Spaces

Epoxy flooring is also gaining popularity in residential spaces such as garages due to its cost-effectiveness, durability, and low maintenance requirements.

Affordability is a key factor in the appeal of epoxy flooring for homeowners. Compared to other flooring options, the initial cost of installing epoxy is relatively low, making it a budget-friendly choice for those looking to enhance their living spaces. The longevity and resilience of epoxy flooring mean that homeowners can save money in the long run by avoiding frequent repairs or replacements.

Gain insights: Can Epoxy Flooring Be Used In Bathrooms

Retail Spaces

Retail spaces benefit greatly from epoxy flooring due to its appealing appearance and ability to withstand high-traffic areas, enhancing both the aesthetics and functionality of the space.

The seamless and glossy finish of epoxy flooring not only adds a modern touch to the retail environment but also creates a clean and professional look that appeals to customers. Its resistance to wear and tear makes it ideal for places prone to heavy foot traffic, such as retail stores and shopping malls. With its durability and easy maintenance, epoxy flooring provides a long-term solution for businesses looking to invest in a reliable and cost-effective flooring option.

Healthcare Facilities

In healthcare facilities, epoxy flooring is preferred for its seamless surface and the option to incorporate anti-microbial additives, making it hygienic and durable enough to withstand the movement of hospital gurneys.

These specialized additives play a crucial role in creating a sanitary environment by inhibiting the growth of harmful bacteria and viruses, thus reducing the risk of infections. The durability of epoxy flooring allows it to resist scratches, stains, and chemical spills, which are common occurrences in healthcare settings. Its ability to handle heavy equipment, such as medical machinery and furniture, ensures long-lasting performance with minimal maintenance.

What Are The Potential Drawbacks Of Epoxy Flooring?

While epoxy flooring offers numerous benefits, it also has potential drawbacks such as the presence of VOCs in some formulations, lengthy installation times, and the need for meticulous surface preparation.

One of the major concerns associated with epoxy flooring is the release of Volatile Organic Compounds (VOCs) during the curing process, which can contribute to poor indoor air quality and pose health risks, especially for individuals with respiratory issues.

The installation of epoxy flooring is known to be time-consuming, requiring multiple steps such as surface cleaning, priming, applying the epoxy resin, and allowing sufficient drying time between coats. This extended process can cause inconvenience, particularly in areas where quick turnaround times are essential.

Ensuring thorough surface preparation before applying epoxy is crucial for the longevity and durability of the flooring. Inadequate preparation can lead to adhesion problems, bubbling, or uneven finish, ultimately affecting the overall aesthetics and performance of the floor.

How To Properly Maintain Epoxy Flooring?

Proper maintenance of epoxy flooring involves regular cleaning and the application of protective coatings to preserve its durability and appearance.

To ensure your epoxy flooring stays in top condition, it is crucial to establish a consistent cleaning routine. Start by sweeping or vacuuming the surface regularly to remove dirt and debris that may scratch or damage the epoxy finish. For a deeper clean, mop the floor with a gentle cleaner and warm water. Avoid using harsh chemicals or abrasive tools, as they can compromise the integrity of the epoxy coating.

Conclusion: Is Epoxy Flooring Right For You?

Deciding whether epoxy flooring is right for you involves weighing its many benefits, such as durability, easy maintenance, and design versatility, against potential drawbacks like installation time and VOC emissions.

One of the main advantages of epoxy flooring is its exceptional durability, making it ideal for high-traffic areas in residential or commercial settings. Not only does it withstand heavy use, but it is also resistant to stains and chemicals, ensuring a long-lasting finish.

The ease of maintenance is a significant benefit, requiring simple cleaning routines to keep the floor looking pristine. Its seamless surface makes it easy to sweep, mop, or even use a mild detergent for tougher stains.

On the other hand, the installation process for epoxy flooring can be time-consuming and may require professional help, increasing the overall cost. Another consideration is the emission of volatile organic compounds (VOCs) during installation, which may pose health risks if not properly ventilated.

My name is Stacey Reid the senior author at Art Syndicate. I enjoy everything homely and everyday I am amazed at the creativity that I find on the internet to write about and the items that I find to sell to our visitors. I cannot however find everything out there as it is very time consuming so please come and take the time to tell us about something new if you think our visitors would like it.

My name is Stacey Reid the senior author at Art Syndicate. I enjoy everything homely and everyday I am amazed at the creativity that I find on the internet to write about and the items that I find to sell to our visitors. I cannot however find everything out there as it is very time consuming so please come and take the time to tell us about something new if you think our visitors would like it.